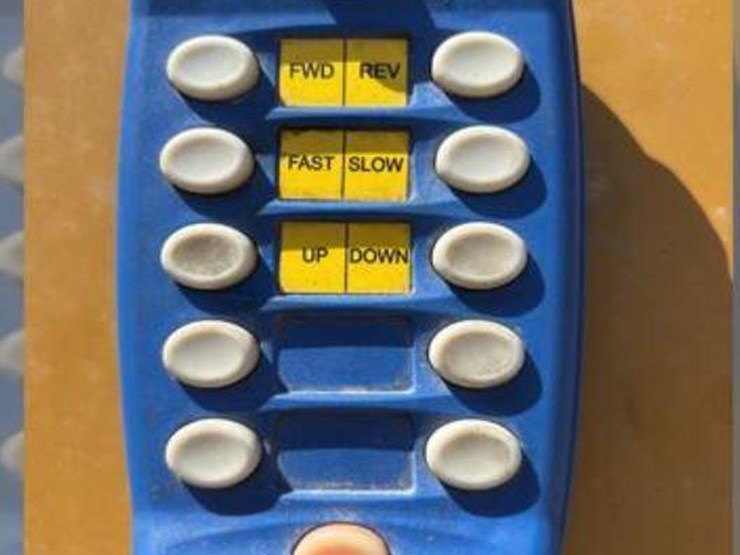

Description: Standard Features: The H-1135 has 12in diameter x 4ft long dual augers for discharging ground product. Augers are mounted with two heavy-duty bearings located at the base of the discharge allowing free flow of product to the stacking conveyor. Expansion of the discharge area allows for higher capacity and reduces possibility for plugging. On the H-1135, the tub rotation feeds the hammermill using a Wachendorf Electronic Control Governor, which stabilizes engine load by adjusting or stopping the tub speed. It also controls tub direction, clockwise, stop, and counter-clockwise as well as tracking total grinding hours and job hours. The newly designed drive system was updated for easier service and maintenance of the H-1135. The drive allows for a much smoother running grinder. The belt drive system for the hammermill has 8-5 VP belts to handle the increased rotor speed and increased horsepower capacity. The spring tension belt drive automatically adjusts belt tension as the belts stretch. Grain grinding with a Haybuster PTO tub grinder has become a very popular use of our hay grinding machines. Installing a grain grinding hopper on the hammermill and changing screens will convert the H-1135 into a high-capacity grain grinder. The H-1135s tub opens a full 90 degrees for easy access to the hammermill and drive train for maintenance and service. Heavy Duty Axle Transport System 445/50R x 22.5 Super Single Tires 16.1 x W14C, 8 bolt rims with 6in pilot hole. Tapered Bearing System. The hydraulic folding 24in wide by 26ft long high-capacity stacking conveyor is designed for the increased capacity of the H-1135. It can stack material 18ft 6in high. The Big Bite 50in heavy-duty hammermill is now standard equipment and is located at the rear of the tub to reduce the length of the discharge. This, along with the increased area around and under the screens accelerates product discharge and reduces the potential of plugging. The heavy-duty hammermill operates at 2140 rpm and is constructed with 88 forged swinging hammers. The hammers are hardened and are held in place with one and one fourth inch case-hardened hammer rods. The hammermill is mounted on a three and a half inch stress-proof shaft supported by three and a quarter inch bearings. Heavy duty bolt in 9 bar mill grate allows operator the ability to remove and add bars as grinding conditions change. Controls tub forward, stop, reverse and speed. Controls conveyor raise and lower. FASTLINE SALES REPRESENTATIVE(s) Joel Allison joel.allison@fastline.com 502-222-8392 Item Location - Address: Provided By Seller Item Location - City: Beemer Item Location - State/Province: Nebraska Item Location - Postal/Zip Code: 68716 Item Location - Country: United States Item Location - County: Cuming County, NE

2022 HAYBUSTER H1135

Bid OnlineLot #93

- Item #

- 80d1ea4d-5dba-4e02-9641-b38400d58a90

- Year

- 2022

- Make

- HAYBUSTER

- Model

- H1135

- ROTATING MATERIAL CHAMBERS

- Yes

- OTHER/NOTES

- 2022 Haybuster H1135 Tub Grinder with 12in diameter x 4ft long dual augers, Wachendorf Electronic Control Governor, hydraulic folding 24in wide by 26ft long high-capacity stacking conveyor, Big Bite 50in heavy-duty hammermill operating at 2140 rpm, heavy duty axle transport system with 445/50R x 22.5 Super Single Tires.

- TIRES

- Single, 445/50R x 22.5 Super Single Tires, 16.1 x W14C, 8 bolt rims with 6in pilot hole, Tapered Bearing System

- Year

- 2022

- Tires

- Single

- Bin

- Folding

- Crop Type

- Grain

- Blade

- S

- Drum Setup

- Single

- Pilot Controls

- Yes

- Thumb

- Hydraulic

- Number of Rear Axles

- Single

- Transmission Manufacturer

- Allison

- Tires or Tracks

- Tires

- Folding

- Yes

Fastline Auctions

- November 4, 2025 11:00 AM